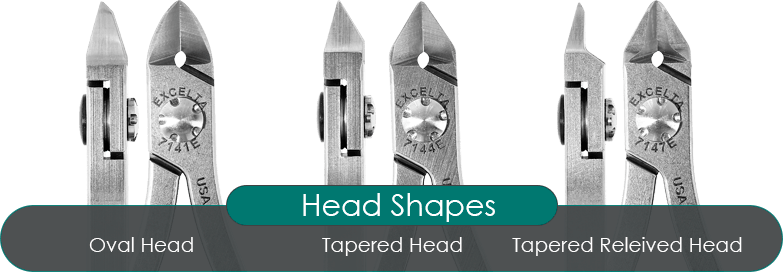

1. Choose head shape based on the following:

- The Oval Head cutter is the most common head for cutting tools. It allows for the maximum amount of ‘metal’ behind the cutting edge delivering an extremely long tool life.

- The tapered Head was developed to allow the cutting tool to get into those “hard to reach” areas. It was designed more along diagonal lines with less “metal” behind the cutting edge.

- The Tapered/Relieved Head allows for the most access to “hard to reach” areas. In addition to having a diagonal profile, the face has been relieved allowing even greater access.

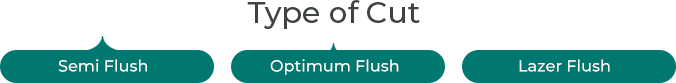

2. Choose 'Type of Cut' based on the following:

- Semi-Flush cutters have a cutting edge with a .010” bevel, which produces more cuts than an Optimum flush cutter but leaves a ‘pinch’ on the wire.

- Optimum-Flush cutters have a cutting edge with a .005” bevel, which produces a smaller ‘pinch’ on the lead/wire than a semi-flush cutter. The smaller bevel means fewer cuts than a semi-flush cutter.

- Lazer-Flush cutters have no bevel producing a pure, clean cut with no ‘pinch’ on the lead/wire. The cutting edges are extremely sharp. Cutting life is once again reduced over either of the above.

3. Find your wire type & size then choose the cutter from this chart:

- Hard Wire - Annealed Stainless Steel, Nitinol, Titanium, Polypropylenes. Tensile Strength 116,000/19,000 PSI

- Soft Wire - Copper Wire, Rubber, Polyurethanes and PTFE. Tensile Strength up to 30,000 PSI